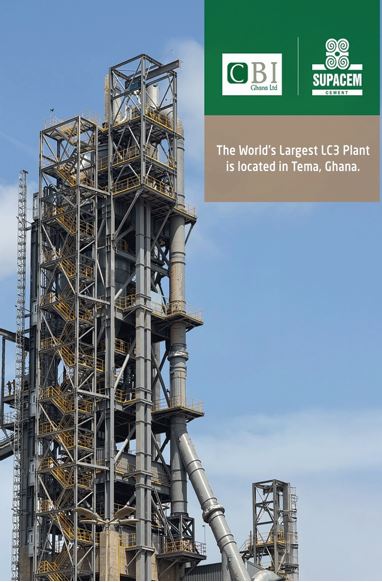

Supacem Cement’s new US$100 million facility in Tema — reportedly the world’s largest Limestone Calcined Clay Cement (LC3) plant — is positioning the nation to reduce its clinker imports amid global supply constraints that have triggered nationwide cement shortages.

The plant processes locally-sourced materials to partially replace imported clinker, the essential binding agent in cement production that Ghana, as Africa’s largest clinker importer, has traditionally sourced from Mediterranean suppliers.

“Supacem Cement has built the world’s largest LC3 plant in Tema, a project that provides a homegrown solution to the clinker problem by tapping into Ghana’s abundant raw material resources as a substitute for imported clinker,” said Supacem Cement in a statement .

This comes as recent price increases and supply disruptions from these markets have cascaded through Ghana’s construction sector, limiting cement availability and driving up costs.

Breaking free from imported clinker reliance

Local cement retailers face growing difficulties, with widespread shortages of cement brands limiting builders’ access to essential materials.

Behind this disruption has been a severe shortage of clinker, a crucial raw material imported for cement production.

The current clinker scarcity and its escalating prices stem from a complex interplay of international supply chain disruptions and evolving global market uncertainties including an increase in the export prices from the Mediterranean rim, a major clinker source.

For Ghana, these global dynamics directly translate into supply shortages and higher costs, ultimately affecting cement availability and prices for retailers and consumers.

Ghana’s cement industry relies heavily on imported clinker, leaving it vulnerable to foreign supply problems and volatile global markets. Supacem’s US$100 million investment into LC3 technology is a key step towards using local raw materials.

The new plant processes locally-sourced raw materials to create a reactive material that partially replaces clinker in cement production, reducing the need for costly and logistically complex clinker imports.

A foundation in national standards

A significant step in enabling this innovation has been the Ghana Standards Authority’s adoption of the latest LC3 standard in 2024. This landmark achievement followed two years of collaboration between Ghanaian institutions like KNUST, the University of Ghana, and Ghana’s BRRI, alongside various international universities and laboratories. This new standard, GS PAS 5:2024, paves the way for the widespread use of this more sustainable and locally-sourced cement.

Supacem’s innovative approach, now supported by national standards, brings numerous benefits to Ghanaians and the economy. By producing a significant portion of their own cementitious material, Supacem reduces the impact of clinker shortages, leading to a more reliable cement supply for Ghanaian retailers and builders.

The project contributes to economic growth and job creation, having established over 160 direct jobs through local sourcing and infrastructure development in Tema and Torgome. Supacem is also empowering local women through dedicated training programmes, expanding opportunities in the industry.

While recent price increases stemmed from port charges, a more cost-effective raw material supply chain could provide greater price stability and cement affordability for consumers across the country. The environmental impact is equally significant, as the production of LC3 significantly lowers CO2 emissions compared to traditional cement production. This supports Ghana’s climate action commitments and contributes to a greener future for the nation.

Supacem’s investment in a world-class cement laboratory is developing Ghanaian talent in advanced LC3 technology, positioning Ghana at the forefront of sustainable cement production in Africa.

The project strengthens Ghana’s local economy by reducing reliance on imports and adding value to local raw materials, thereby reducing the country’s vulnerability to external economic factors. This comprehensive approach creates benefits that extend far beyond the immediate cement industry, contributing to national resilience and sustainable development.

Supacem has taken the lead in transforming Ghana’s cement industry. The company has extended its supply of locally produced LC3 raw materials to Ghacem, Ghana’s largest manufacturer. This move further reduces clinker imports and highlights Supacem’s commitment to industry-wide sustainability and building a more resilient and self-sufficient cement sector in Ghana.

Emmanuel Cherry, CEO of the Ghana Chamber of Construction Industry, has called for the exploration of local alternatives for clinker. Supacem’s investment, supported by the GSA’s adoption of the LC3 standard, answers this call, showing the potential of Ghanaian ingenuity and resources to address critical industry needs.

Supacem’s bold initiative offers a tangible solution to the current cement shortage and builds a foundation for a more sustainable, self-reliant, and environmentally responsible cement industry in Ghana. This major step by a Ghanaian company is about building infrastructure and a stronger, greener, and more prosperous Ghana.