Unleashing the Magic Bullet for Cost Reduction

Over the last six episodes, we’ve delved into the science and practice of Lean and Six Sigma (LSS). We have created a road map for organisations interested in embarking on this journey. The LSS imperative is more important now than ever. We’re heading for a stagflationary crisis unlike anything we’ve ever seen. Roubini, a professor of economics at New York University’s Stern School of Business and the founder and chairman of Roubini Global Economics, has intimated in a Bloomberg interview that a recession is likely to hit the U.S. by the end of 2022 before spreading globally next year – conceivably lasting for the entirety of 2023. “It’s not going to be a short and shallow recession; it’s going to be severe, long and ugly.”

The Cost-Efficiency Imperative

Traditional definitions of the cost of operations imply that all costs incurred in the delivery of goods and services are inherently necessary. However, many other tangible and intangible costs are hidden in these costs as a result of poor quality and poor operational practices. Inefficiency is costly. Rework is costly. Re-handling is costly. Examine each process; the issues revolve around a number of parameters such as stability, reliability and capability.

LSS ensures stable processes capable of meeting clients’ needs and requirements… while also delivering the level of reliability required to ensure that products and processes are not prone to failure in a variety of changing and varying scenarios. As the world’s economy struggles, cost-efficiency becomes a top priority for every organisation. Businesses have two options: the traditional approach, which has always backfired… or Six Sigma’s scientific, methodical approach.

The Problem-Solving Imperative

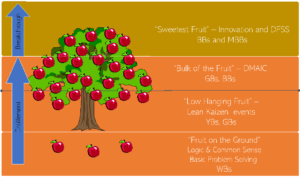

Problems are of two types – solutions known and unknown. Let’s leave the solutions known problems for Project Managers to handle. But for those solutions for unknown problems – this is where LSS practitioners come in. Using a time-tested and truly trusted [pun intended] methodology, these practitioners get to the root cause of problems and deliver lasting solutions to organisations of all types and sizes.

Let’s Tell the Stories

Does Lean Six Sigma work? I have heard this question many times. So, I tell the stories. I tell stories about how over the past 18 years, as an FTE and as a consulting enterprise, I/we have taken this methodology to many industries – (manufacturing [automotive, printing, FMCG, pharmaceutical], mining and financial [commercial banks, savings and loans, microfinance], telecommunications, downstream oil and gas, etc.), and practically shown how LSS helps to reduce costs, streamline operations, improve the culture of empowerment and problem-solving, and impact the bottom lines of organisations. So, let us tell some of these stories here:

Service Excellence in the Commercial Banking Industry

We have used the power and science and also provided roadmaps to clients in the commercial banking sector… For one client, we showed the potential of cost savings in excess of GH¢50m by deploying about 15 improvement initiatives:

- Reducing offsite ATM downtime mean time to repair (MTTR) from an average of 4-5 hours to an average of 1hr 35min – an improvement of 73% – with an annual revenue realisation potential estimated in excess of GH¢2.5m.

- Reducing the TAT on account opening from an average of 40 hours down to 23min- cost of poor quality reduction in excess of GH¢100k and defect reduction from an average of 35% down to 0.5%

- We have shown, for instance, the potential for reducing the RTS incidences from an average 35% to less than 5% – delivering a 25% increase in daily loan disbursements

Manufacturing Industry

- For one of our clients, bursting jerry-cans from a blow-to-fill operation had an associated internal and external failure cumulative cost of US$600k. An initial LSS project helped to deliver a 16% cost reduction.

- For one FMCG manufacturer, we leveraged the power of LSS to reduce compressed air leakage by 32%; with an attendant energy reduction of 15,000Kwh per week leading to US$108k per annum savings.

- For another client, the pain was the incidence of dented and scratched cans on a production line. Our team went to work , and within the first three months of deployment the defects reduced by an average of 60% – yielding cost savings in excess of US$53k per annum.

- Using a Lean single-minute exchange of dies (SMED) methodology, this client’s LSS team reduced the changeover TAT on a plastic-blowing line by 29% with estimated savings of US$285k.

- By deploying a hybrid CONWIP-Kanban system in the finishing and warehousing operation of a direct mail printing facility in the UK, we reduced standard waiting times to zero for replacement stock., experienced changeover time reductions by as much as 84%; space requirements in the holding area reduced from 6 lanes to 1 lane, and reduced WIP inventory by 60%.

Downstream Oil Marketing Industry

- A team that we deployed to a downstream OMC used LSS for reducing negative variance on fuel-pump stations. The intervention led to a reduction in cumulative negative variance from 0.75% to 0.02% within the first three (3) months post-implementation. with a resultant potential cost savings of GH¢33k per annum

- This same client used the LSS methodology to reduce gasoline fuel shortages at fuel stations. A rigorous LSS deployment helped see shortages reduced to an average of 0.50%, delivering annual savings potential of US$88k per annum.

Mining

Whether in the pit or the plant, we have identified ways of reducing the cost of mining operations. This equation has meaning to every mining executive: (g * t * r * P ≥ CM + CP + CGA [Grade * Tonnes * Recovery * Price] ≥ Cost of Mining + Cost of Processing + Cost of General Administration. Our mining clients have over the years used LSS to reduce mining and processing costs significantly. A few of them are outlined here:

- A data-based LSS approach was deployed to help this client reduce pit wall instability due to fault planes and the presence of groundwater, delivering a cost avoidance of US$6.2m per every potential wall collapse.

- Another client used Six Sigma to reduce the variance in the tonnage ore loss to ± 4% by mining to ripple angle with financial savings of US$680k.

- This very HV client used the power of LSS data analysis to reduce gold solution loss to tails from an average 0.2g/tonne to 0.05g/tonne, with a potential revenue potential of over US$2m per annum

- A team deployed at a client’s plant used the SMED methodology to increase the elution strip rate by 36%, to deliver at least 1.5 strips with monthly cost savings of over 0.8% (approx. US$1.4m)

- Manufacturing – used LSS to reduce power consumption, leading to cost savings

- Banking – We have helped clients to reduce, and identified ways to reduce, the cost of account opening, Treasury bills rediscounting; thus reducing cost.

As You Start Your LSS Journey…

What do you need? The answers to this very broad question also provide the framework to reduce the potential of failure in your programme.

- Committed and strong leadership is absolutely essential – often, this is a major cultural change.

- Six Sigma approach and other existing initiatives, strategies, measures and practices must be integrated – Six Sigma must be an integral part of how the organisation conducts its business.

- Quantitative analysis and statistical thinking are key concepts – it is data-based managing.

- Constant effort must be applied to learning everything possible about customers and the marketplace – intelligence gathering and analysis is critical.

- The Six Sigma approach must produce a significant payoff in a reasonable time period – real, validated dollar savings is required.

- A hierarchy of highly-trained individuals with verified successes to their credit, often referred to as Master Black Belts, oversee the Black Belts and Green Belts needed to extend the leadership to all organisational levels.

- Performance tracking, measuring and reporting systems are needed to monitor progress, allow for course corrections as needed, and link the Six Sigma approach to the organisational goals, objectives and plans. Very often, existing performance tracking, measuring and reporting systems fail to address the level where they are meaningful to the people involved.

- The organisation’s reward and recognition systems must support continual reinforcement of the people, at every level, who make the Six Sigma approach viable and successful. Compensation systems, especially, need to be reengineered.

- The successful organisation should internally celebrate successes frequently -success breeds success.

- To further enhance its image and the self-esteem of its people, the successful organisation should widely publicise its Six Sigma accomplishments and, to the extent feasible, share its principles and practices with other organisations – it should be a member of a world-class group of organisations that have committed their efforts to achieving perfection.