In 2017, a German investor who initially came to Ghana to explore the viability of a solar business ended up establishing the first cocoa-pulp manufacturing factory in Ghana. They recently also launched their blockchain-based transparency system to demonstrate to their customers how much they pay their partner farmers. While this business venture converts what was initially a waste material into products of economic value – creating an additional income stream for the farmer, it shouldn’t be left unscrutinised. As a Ghanaian cocoa farmer’s son, I remain sceptical of sweet talks from Western investors using ‘ustainability’ as their talking point when describing the impact of their venture. At least, Fairtrade has taught us a lesson on how they can help chocolate companies and governments’ virtue signal about their ‘sustainability ambition’ while pushing its cost to the ordinally poor smallholder cocoa farmers.

So, I interviewed some of KOA’s management members to understand their business and probe further to understand their transparency system. This series of articles will focus on exploring the business operations of KOA, their radical transparency digital platform, and my concluding thoughts on each. Ultimately, KOA is doing what Ghana Cocoa Board has refused to incentivise indigenous Ghanaian investors to do, i.e. cocoa by-product processing. With the cocoa sector remaining a blue ocean, its by-product commercialisation has massive potential. However, Ghana Cocoa Board has focused on wasting resources on strategies with short-term and long-term effects on cocoa farmers’ livelihoods. That is, increased cocoa production with a harmful impact on price and increased barriers to entry by indigenous Ghanaian investors.

Let’s get it going!

Who is KOA, and what is their interest?

KOA is a cocoa pulp processing company registered in Ghana and Switzerland. In Ghana, they are in Assin Akrofuom in the Central Region. They highlight that KOA came into being after its founders’ unsuccessful Solar Business Development in Ghana in 2017. However, the founders’ first taste of cocoa pulp, its delicious taste, and the fact that no one in Ghana added value to the cocoa pulp became an opportunity they felt was worth exploring. To ensure that their potential company (now KOA) make a social impact, they researched and engaged farmers directly to understand how they (KOA) could secure their trust and co-design an operations process suitable for them.

The core of the numerous issues they realised was the enormous burden the cocoa chocolate value chain put on the farmer, and the level at which no investment has been made in the by-product value addition to help raise the net income of farmers to be able to deal with the burden levied on them. They also realised how sustainability by various organisations that work with farmers was narrowly focused on ‘the environment’ with less focus on the people, their community and their net income. So their business was essential to demonstrate how a tripartite sustainability approach could be implemented, significantly impacting the farmer’s income, community and environment.

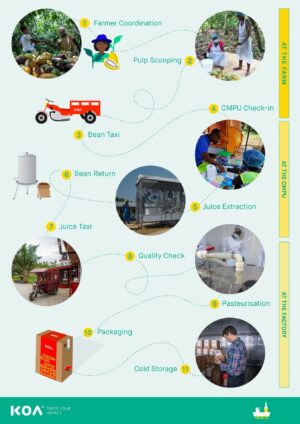

So, before they incorporated the company, they acknowledged that cocoa pulp processing required the borrowing and returning of the farmers’ wet beans; hence, earning the farmers’ trust and mutually designing a procurement and handling system that both parties were happy with was essential. So, they sought the stakeholder engagement expertise from their Ghanaian colleagues to meet with the farmers and discuss what KOA needed to do to earn their trust to make this new business sustainable. This stakeholder engagement led to implementing a decentralised system where KOA handles the evacuation of the wet beans from the farmers’ pod-breaking area for processing and returns the beans to the fermentation area as agreed by the farmer (Ref to Pic 1).

As indicated in Fig 1, going to the farm in this context means KOA creates a central location in the farming community where their mobile processing unit is. With the aid of tricycles, KOA goes to each of their client’s (The farmer) farms to evacuate the wet beans to their mobile processing units and returns them to the farmer at their cocoa beans’ fermentation area. KOA fully caters for the cost of transportation services. In this case, the cocoa pulp processing isn’t only bringing the farmer an extra net income; it’s also decreasing the cost of producing the dried cocoa beans. As compared to some chocolate companies that have entered commercial cocoa production as a solution to smallholder farmers’ livelihood (The irony of it), KOA instead supports the farmer to be efficient at producing dried cocoa beans which even isn’t an input KOA’s need for its cocoa pulp processing, at least for now.

Pic One: KOA’s value Chain and Decentralised operations system were designed with the Farmers

To read the full article and support my research work, kindly make a paid subscription to my newsletter via https://cocoadiaries.substack.com/subscribe.

A Cocoa Farmer’s Son with expertise in international trade & policy, industrial policy, and project management, with a professional focus on the cocoa-chocolate industry, the smallholder cocoa farmer and the digital economy.

- Newsletter: https://cocoadiaries.substack.com/subscribe

- Twitter:@asamoahpeters

- Email:[email protected]

- LinkedIn:Kwame Asamoah Kwarteng